Category

Hopper Feeding Device and Shut

Electric air lock XG type electric feeder is used for air lock and uniform feeding when conveying dry powder materials.I

Basic Info.

| Model NO. | SSI-SQQ |

| Condition | New, New |

| Certification | RoHS, UR, ISO, CE, CCC, CE, ISO, CE, ISO |

| Screen Mesh | All Available |

| Pellet Mill Type | All Available |

| Grinding Equipment Type | All Available |

| Processing Technics | All Available |

| Processing Object | All Available |

| Character | High Performance |

| Benefit | Low Maintenance |

| Advantage | Durable |

| Expanding Method | All Available |

| Feature | Reliable |

| Bulking Machine Type | All Available |

| Warranty | 1 Year |

| Type | Customization |

| After-Sales Service | ["1 Year","1 Year"] |

| Applicable Materials Shape | Granular |

| Finished Dosage Form | Customization |

| Voltage | 380V |

| Customized | Customized |

| Computerized | Computerized |

| Precision | High Precision |

| Transport Package | Nude |

| Specification | Determined according to the project |

| Trademark | SSI |

| Origin | China |

| HS Code | 8419609090 |

| Production Capacity | 100 Sets / Year |

Product Description

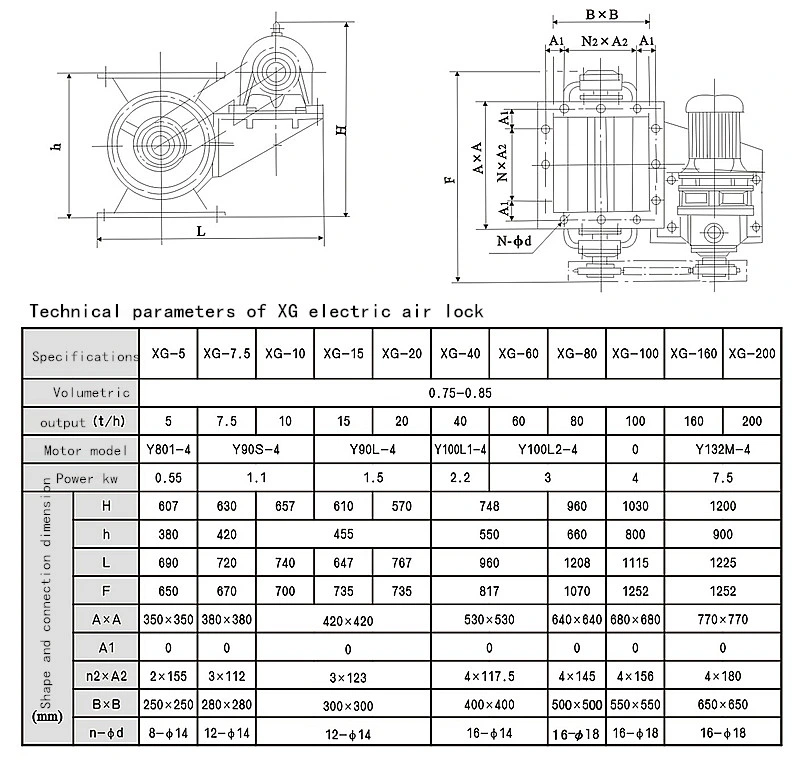

Electric air lockXG type electric feeder is used for air lock and uniform feeding when conveying dry powder materials.It is widely used in cement plant, chemical plant and thermal power plant.It is installed in the lower part of ash hopper such as electrostatic precipitator and air preheater in thermal power plant.The working temperature of the machine is allowed to reach 200 ºC, and it can be increased to 450 °C if special orders are made.The features of this series of products are good sealing, wear-resistant shell, light weight, easy to arrange and maintain.The machine can also be equipped with frequency modulation motor or other speed regulating motor to obtain different output.

We are a professional company in bulk material handling, transportation, storage, processing, accessory equipment design, integration and manufacturing. We can provide a complete set of solutions. Thank you for reading the information and welcome to purchase! Welcome to agent distribution!

Brief introduction of the company's manufacturing capacity

The company's headquarters, technology and sales are located in Lingang New Area of China (Shanghai) pilot free trade zone,The company's processing base is located in "China's most beautiful county" Tonglu County, Zhejiang Province, 65 km from Hangzhou, 60 km from Qiandao Lake, rail, road, water transport is extremely convenient .The company has first-class processing equipment and facilities, the total plant covers an area of more than 30,000 square meters, the workshop is equipped with more than 300 sets of various processing equipment,Among them, nearly 20 sets of CNC precision large-scale equipment (smvtm1200050/150, dvt800030/32, ck61315125/32, ck6120080/32, CNC boring and milling TJK6920, etc.) basically achieve CNC machining,At the same time, the annealing furnace 10.5 M 8m 8M, the maximum lifting capacity of 25 T, 50 T, 100 t of all kinds of lifting facilities, can meet all kinds of large components processing combination and assembly needs.

Products and services available

Handling equipment

Storage equipment

Conveying equipment

Feeding equipment

Supporting equipment of conveying system

Belt conveyor parts

Large and medium sized finishing parts

If you need products, please contact us!

Shanghai Sunshine Industrial Technology Co. , Ltd.