Sanyuantang Tumbler Screening Machines, Tumbler Sieve, Tumbler Screener

Basic Info.

| Model NO. | YBS1200, YBS1600, YBS2000, YBS2200 |

| Shaft Number | Single |

| Running Track | Circular Vibrating Screen |

| Supporting Device | Coil Spring |

| Warranty | 12 Months |

| Customized | Customized |

| Condition | New |

| Power | 0.25-3(Kw) |

| Deck | 1-5 Decks |

| Phase | 3 Phase |

| Mesh Type | Woven Wire or Punching Hole |

| Material | SUS 304/316 or Carbon Steel or as Customer Request |

| Transport Package | Standard Export Plywood Case |

| Specification | 1000-2200mm |

| Trademark | Sanyuantang |

| Origin | Xinxaing, Henan |

| HS Code | 847410000 |

| Production Capacity | 200 Set/ Month |

Product Description

Sanyuantang tumbler screening machines , tumbler sieve , tumbler screener

Product Description of tumbler screen / swing sieve machine

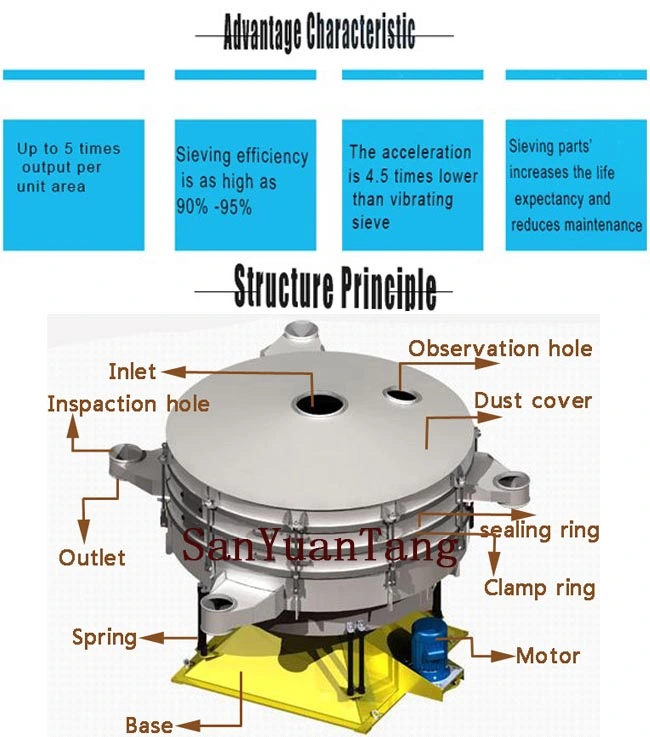

Tumbler screening machine is a kind of inertialequipment with mature technology and classical application.Its new design Philosophy and unique structure making it the closest manual screen machine.

Parameter of tumbler screen

Model | Availability of screening area (m*m) | Screen slope (angel) | Grain size(mm) | Frequency(r/min) | Double amplitude(mm) | Power(kw) | Process capacity(t/h) |

HXSY -1000 | 0.785 | 0-10 | ≤100 | 750 960 1500 | 5-8 | 1.5 | 8-15 |

HXSY -1200 | 1.13 | 5-8 | 2.2 | 15-30 | |||

HXSY -1600 | 1.83 | 5-8 | 2.2 | 25-50 | |||

HXSY -2000 | 2.63 | 5-8 | 4.0 | 30-60 | |||

HXSY -2600 | 5.31 | 5-8 | 5.5 | 45-60 |

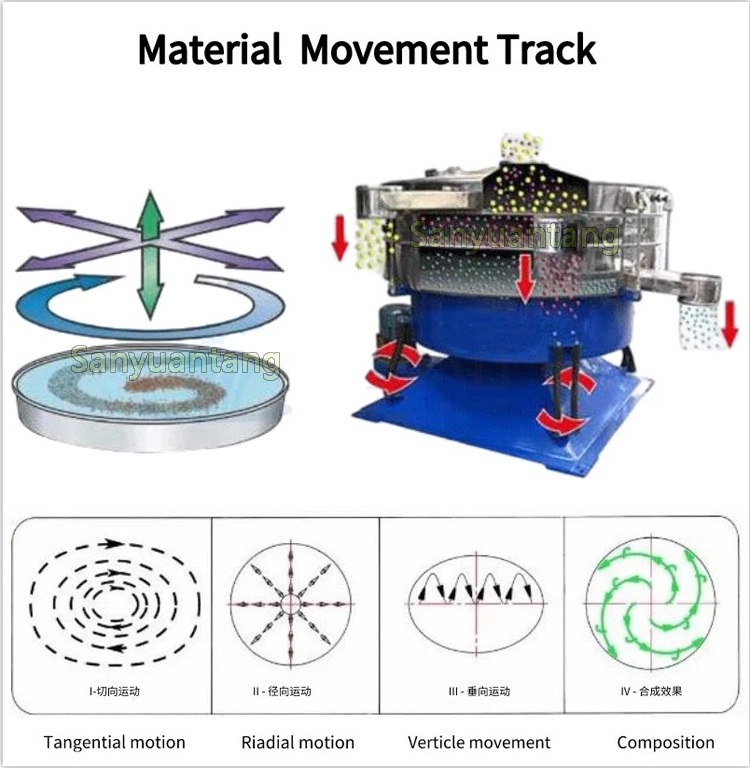

Working Principle of swing sieve

Applicable Industries

The Tumbler sieve machine is particularly used to classify small materiels and fine powder according to its unique structure and working principle. It is not only apply to dry sieving, but also wet sieving.Widely used in various industries.

1.Chemical industry: resin, pigment, cosmetic, coatings, Chinese medicine powde.

2.Food industry: sugar powder, starch, salt, rice noodle, milk powder, egg powder, sauce.

3.Metallurgy, Mine industry: aluminum powered, copper powder, ore alloy powder, welding rod powder.

4.Medicinal industry: all kinds of medicine.

5.Waste treatment: disposed oil, disposed water, disposed dye waste water, active carbon.

Actual picturesWorking pictures

The proper selection of the vibrating screen depends on the material, mesh size, output required, method of input etc:

1. Name of your raw material: _____

2. Moisture:_____%

3. Specific gravity:___kg/m3 or ___ g/cm3

4. Capacity:________kg/ hour

5. Screen layer:_______ layers/decks.

6. Screen mesh size:______ mm . ______ mm. ______ mm

7. Voltage:______V, Frequency:______HZ, 3 phase

8. If CIF please tell me your destination port name .

If you want to know more about tumbler screen, please contact me.